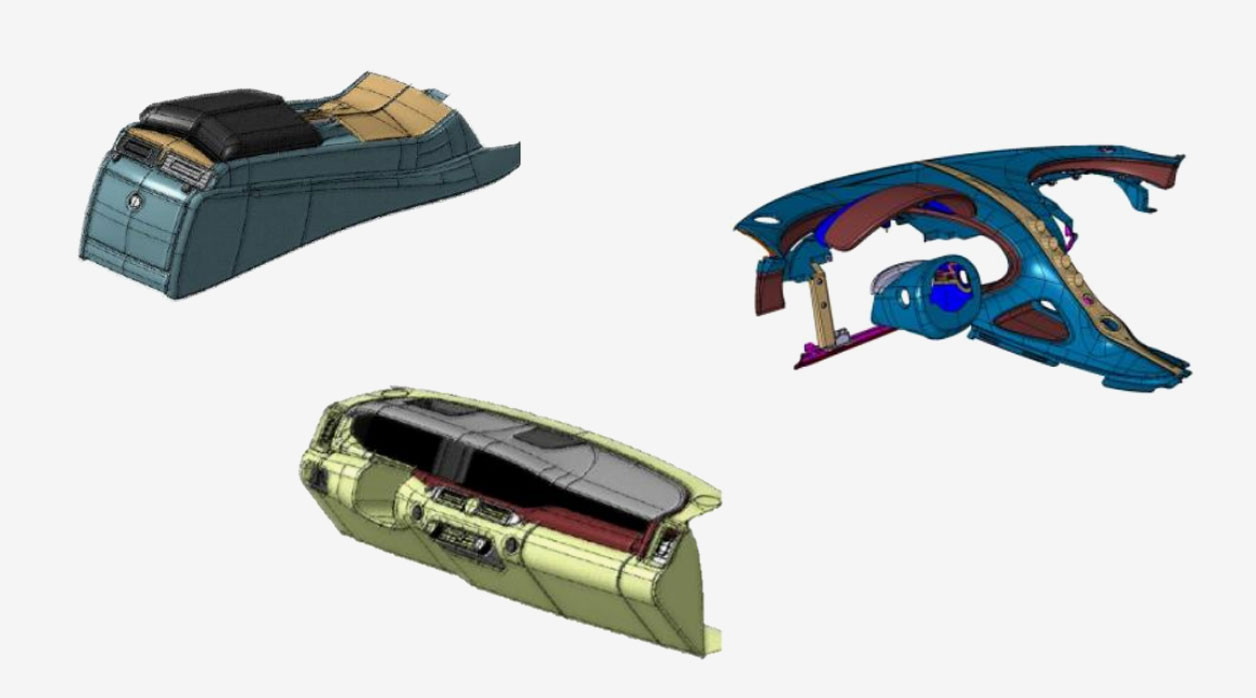

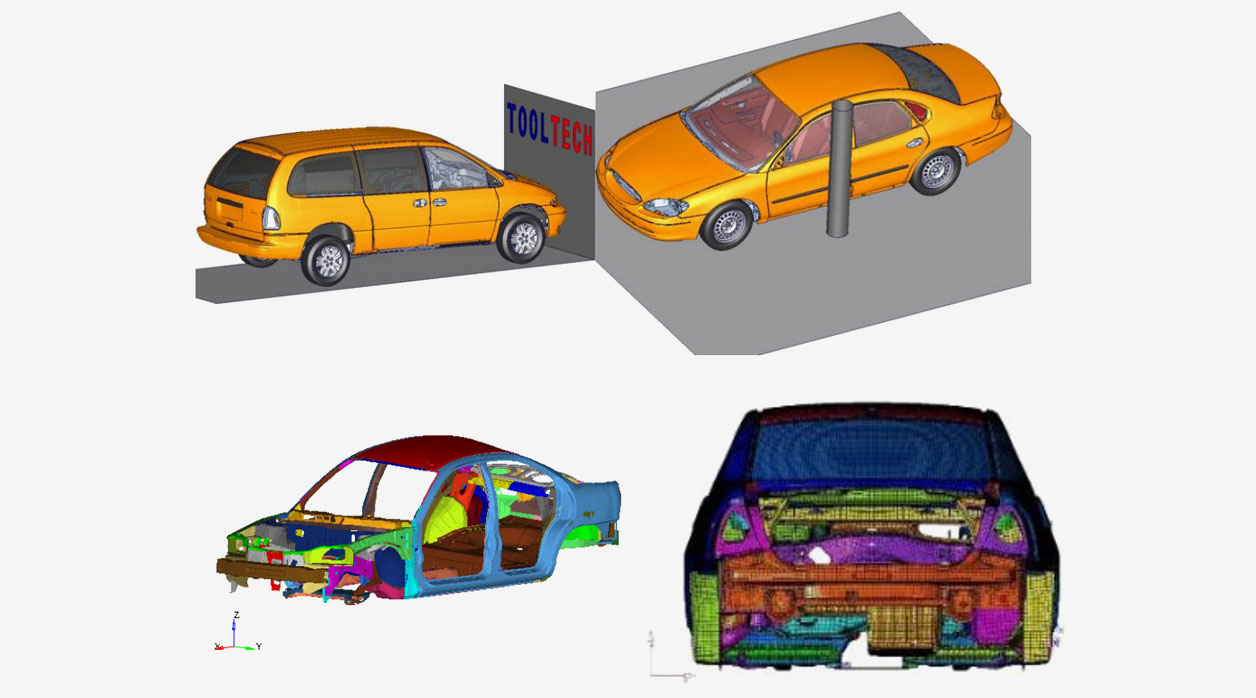

We deployed a dedicated onsite interiors engineering team with one of the big three German automakers, supporting interior trims and systems including luggage compartments, door trims, instrument panels, pillar covers, center consoles, side trims, and headliners. Our scope covered the full range of engineering tasks—concept proposals, packaging studies, master section creation, CAD modifications, closed volume development, and PLM integration— ensuring styling, safety, and manufacturability requirements were consistently met.

Key engineering contributions:

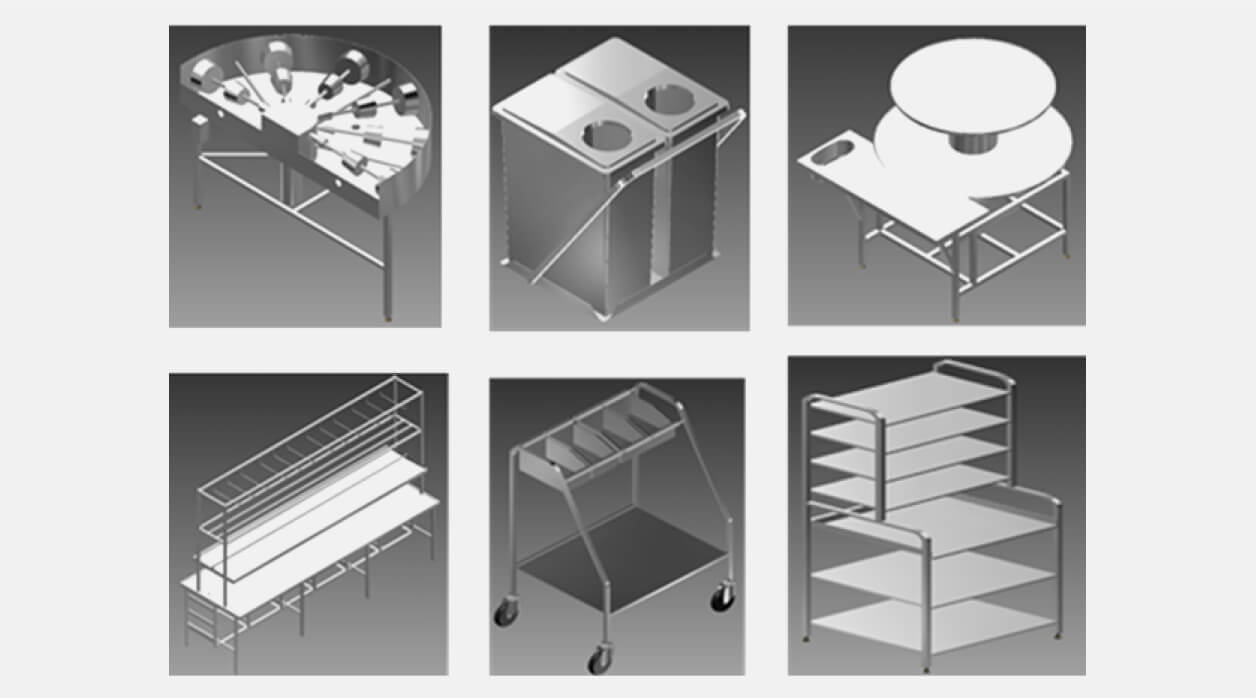

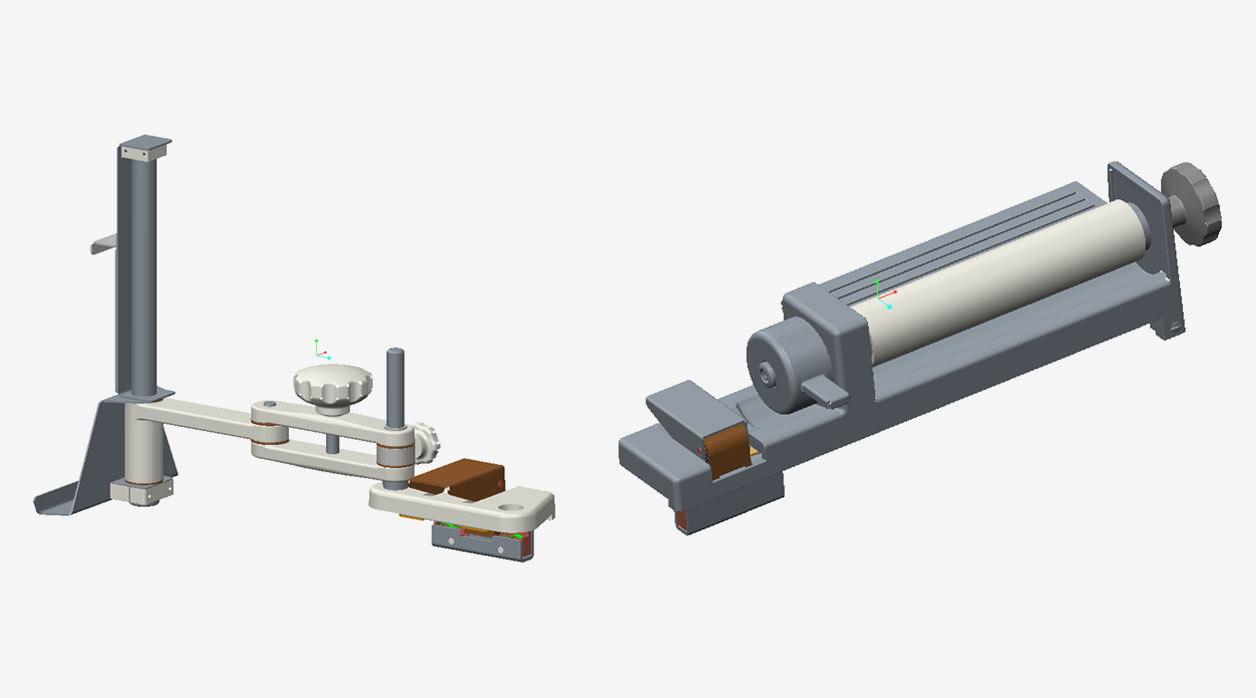

- Plastics and sheet metal part design with domain specific packaging, tooling and manufacturing feasibility

- Working mechanism and closure systems along with kinematics

- CAD data creation in NX as per client standards and release in their PLM environment

- New product development from scan data with alternative solutions.