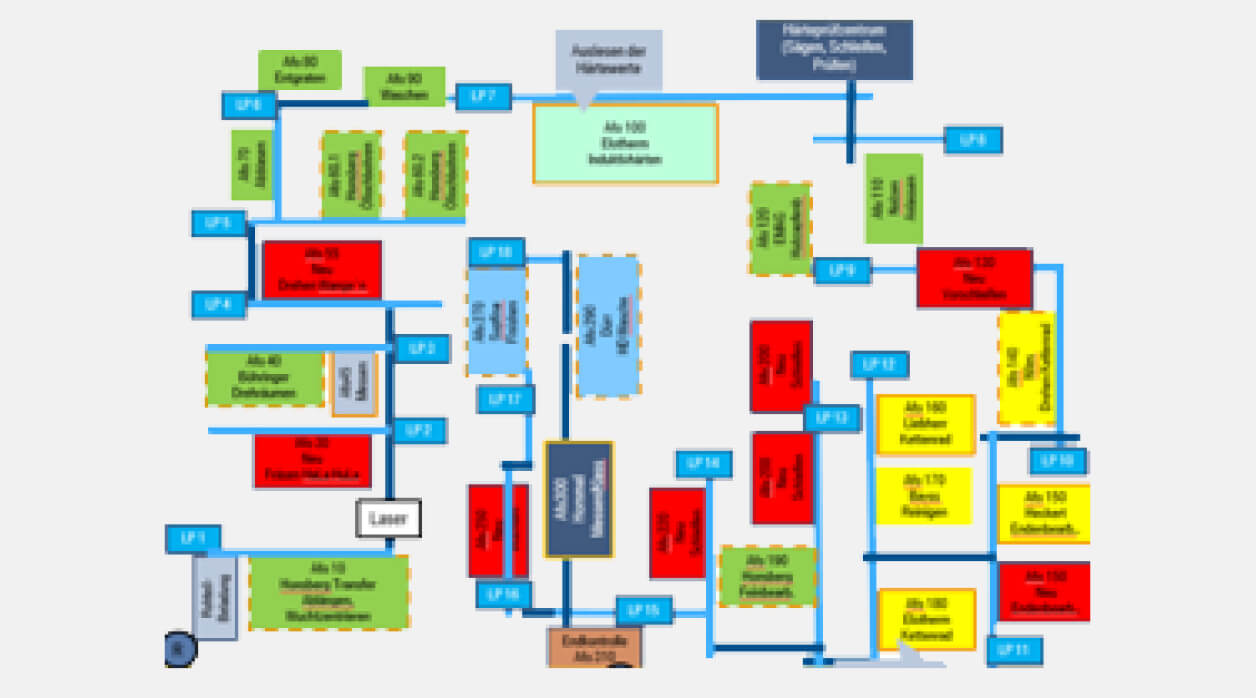

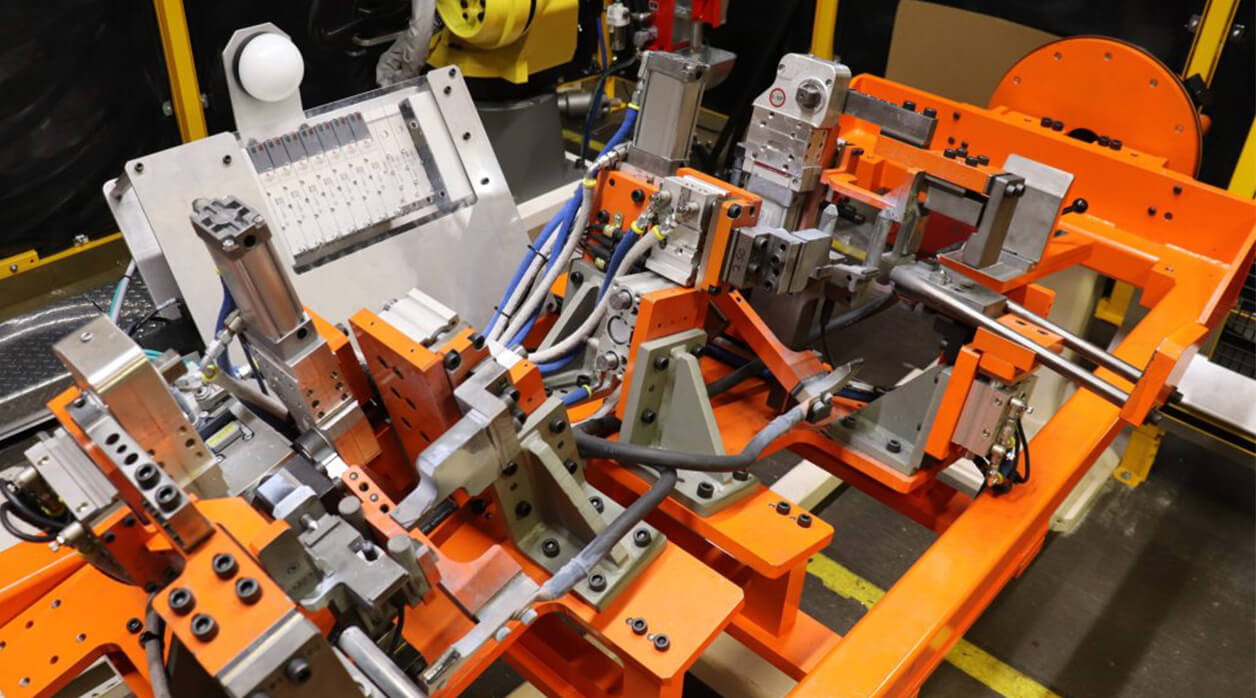

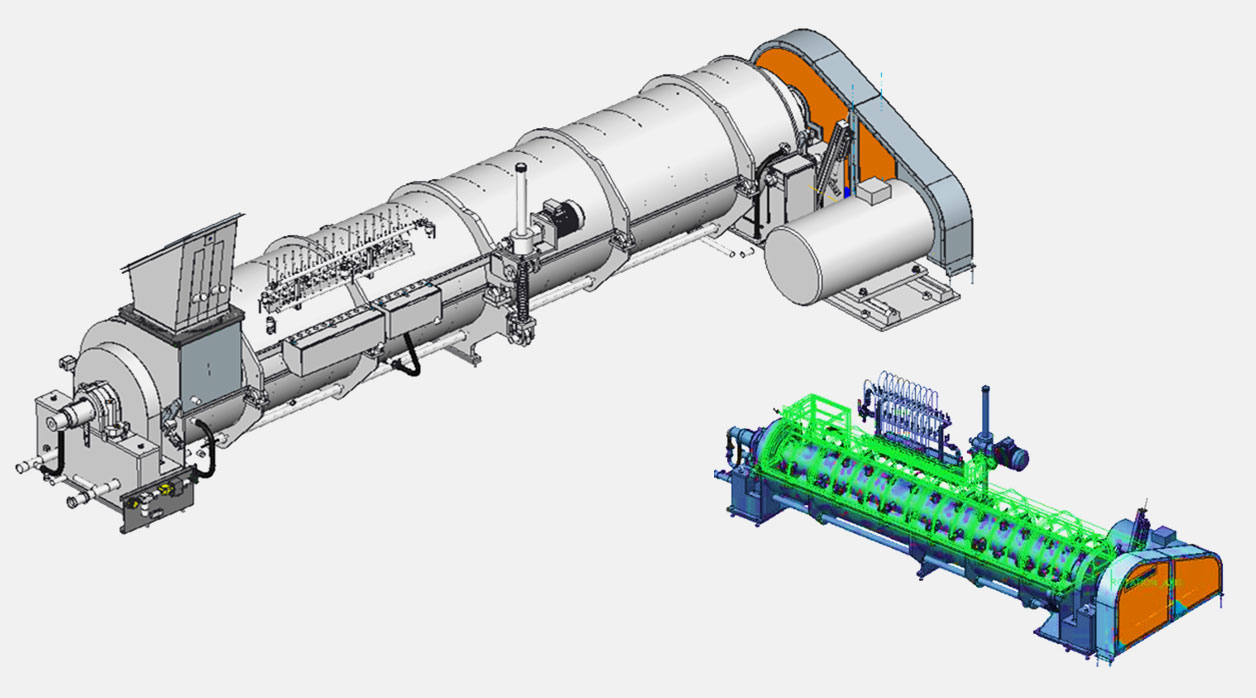

We developed a detailed plant and gantry layout for a crankshaft machining line with 21 machines. The project involved designing operation stations, beams, carriages, safety fences, and conveyors, along with manufacturing drawings and BOM creation. Using SolidWorks, AutoCAD, and Microstation V8i, we integrated 2D layouts into a 3D model, ensuring seamless alignment with existing plans. A hybrid onsite-offshore model enabled efficient execution over 12 months.

Gantry Layout for Crankshaft Machining Line