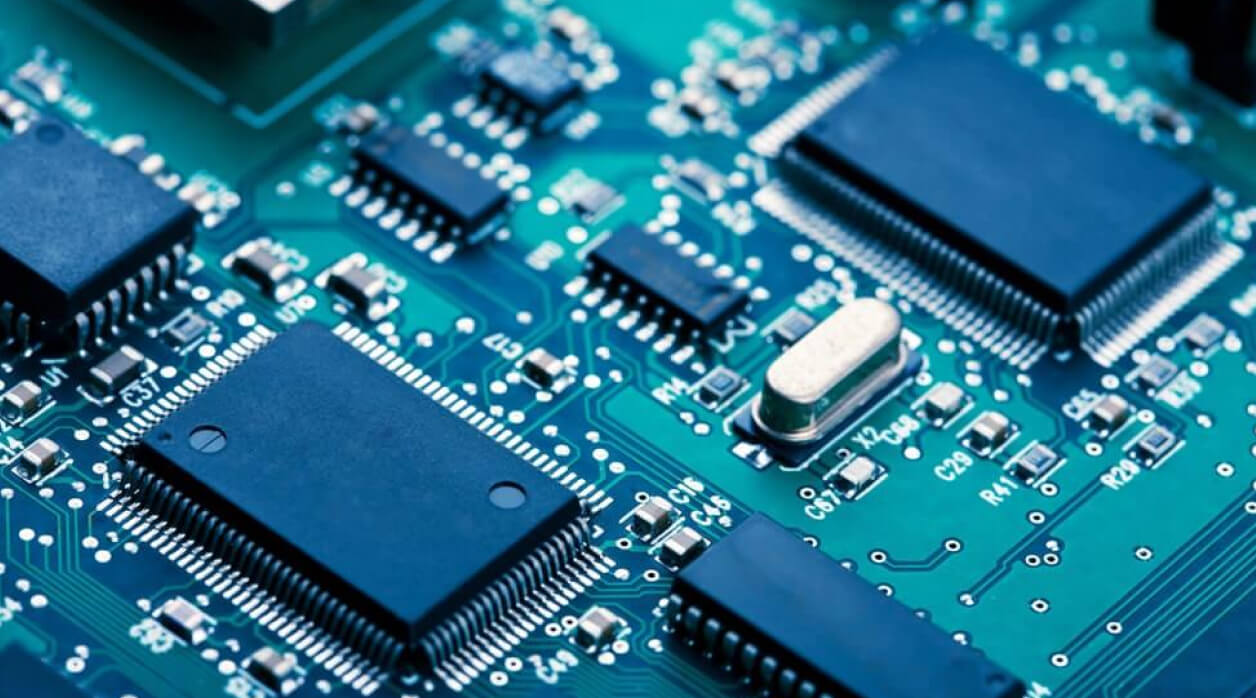

A Scandinavian welding solutions manufacture approached us for the design optimization and localisation of an automated welding machine. We designed the PCBs for the UI membrane panel, integrated main circuit and EMC filter making some design changes in the process. We also designed the schematics for the main circuit board and the UI membrane. We re-evaluated the assembly and re-arranged various parts so that heatsink commonisation could be achieved.

Electrical Design Optimization And Localisation

Other Case Studies