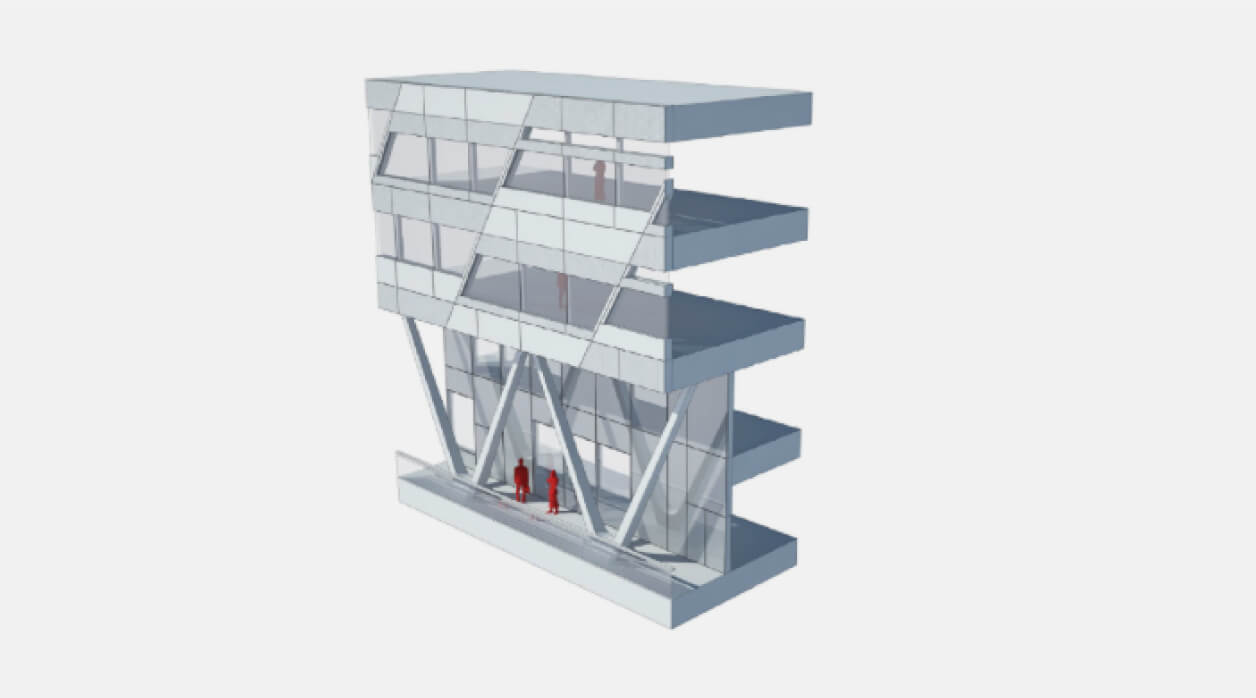

A leading glass façade manufacturer was looking for a partner to help them implement a project in 3D. Prior to this t the client worked exclusively in 2D. We implemented the mix model wherein our engineer worked at the client location in order to understand their working methodology and managed an offshore team for support on live projects.

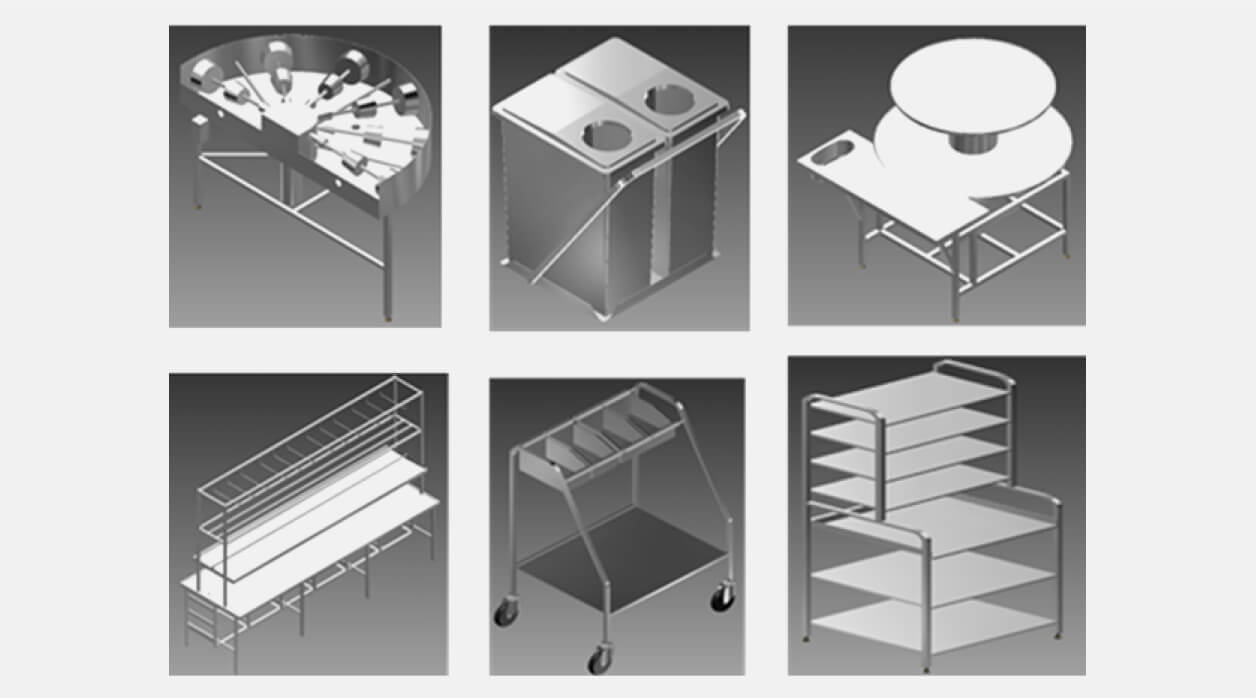

Tooltech developed the façade assembly framework, integrating aluminium profiles, connectors, supports, and panel holders, along with detailed drawings for assemblies, sub-assemblies, and safety components like fire and cover plates.

Our deliverables were 2D drawings and 3D data of elements which would serve as direct input to CNC machines for manufacturing. Overtime the customer moved to using 3D for all their projects and the need of 2D drawings for individual profiles was eliminated.