Conversion of Mixing Barrel into a PED-Compliant Pressure Vessel

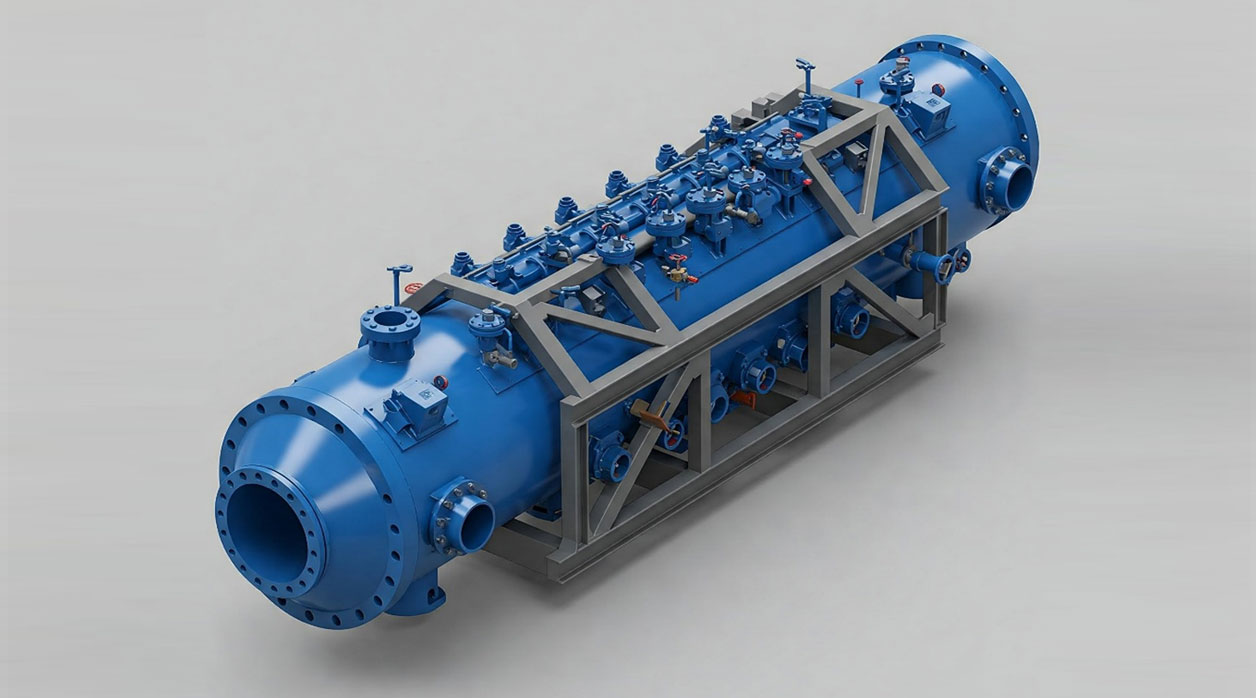

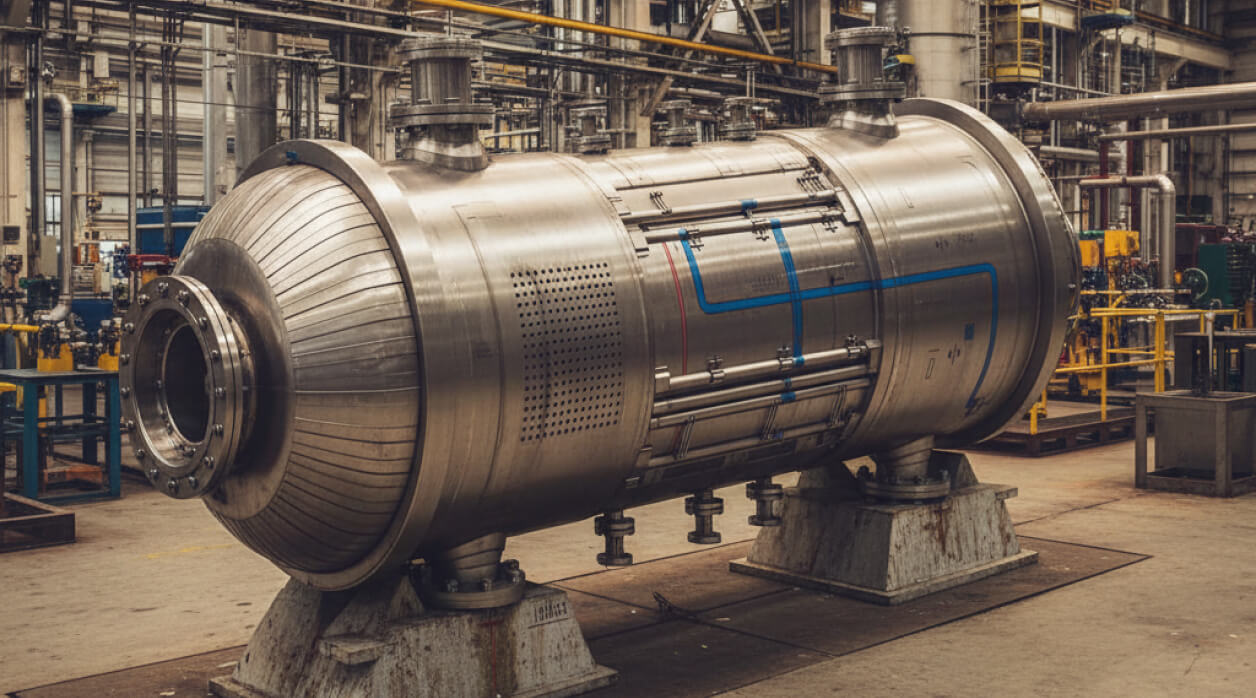

Tooltech redesigned a mixing barrel into a PED 2014/68/EU-compliant pressure vessel.

The project involved 3D modeling, material selection, strength analysis, and compliance with EN13445 standards. Key tasks included optimizing the pressure-bearing structure, performing pressure calculations, and generating 2D manufacturing drawings.

Welding specifications were updated as per EN standards to ensure safety and reliability. The final deliverables included 3D models, strength reports, and manufacturing drawings for PED approval.