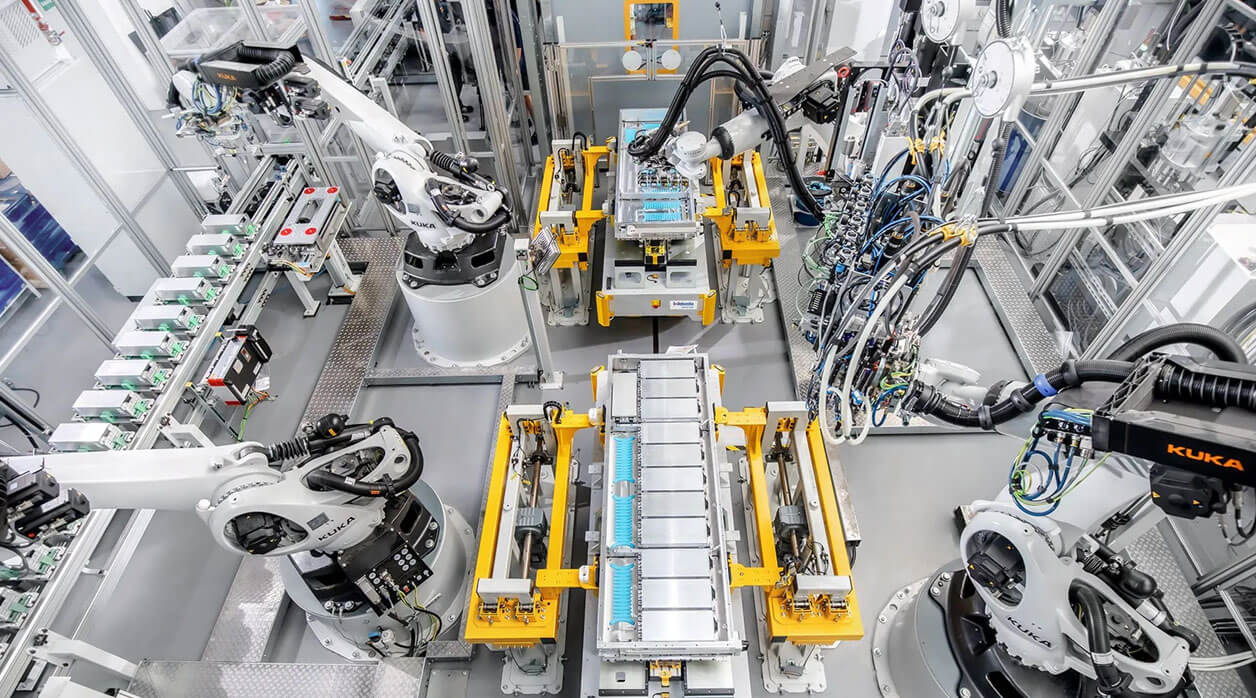

Tooltech partnered with a leading German systems supplier for the commissioning of a powertrain manufacturing plant. The project involved machine building, commissioning, gantry interfacing, and final run-off. Key tasks included software loading, cycle testing, gantry system integration, and automation sequencing. The final phase ensured the complete installation of the cylinder block line, software logic implementation, and production readiness. Additionally, Tooltech trained the client’s maintenance and controls engineering teams for seamless operations.

Powertrain Manufacturing Plant Commissioning